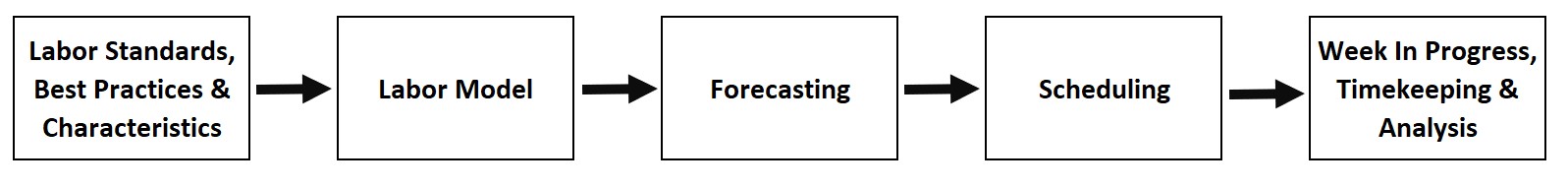

There are several components involved in building a workforce management system capable of delivering competitive advantage to retailers. If you depict those components in simplified process order, you typically get something like this:

While this is a simplified depiction, it highlights the central role of forecasting as the linchpin in the WFM component chain. Unlocking the higher value proposition of all these components relies heavily on accurate forecasting to deliver the upstream and downstream potential of each of the other components.

In this post, we will discuss why that’s the case and why the new layers of benefits are exposed using artificial intelligence (AI), near real-time data exchange, machine-based learning (ML) algorithms, faster cloud-based enterprise computing, applied industrial engineering, and smart retailing. Leveraging the potential of emerging technology will unlock competitive advantage for those who invest in it.

What’s new in forecasting?

Faster computing platforms coupled with AI and ML algorithms have led to breakthroughs in forecast accuracy. The combination of better math and faster processing can out-gun older, static approaches to every step of the forecasting process.

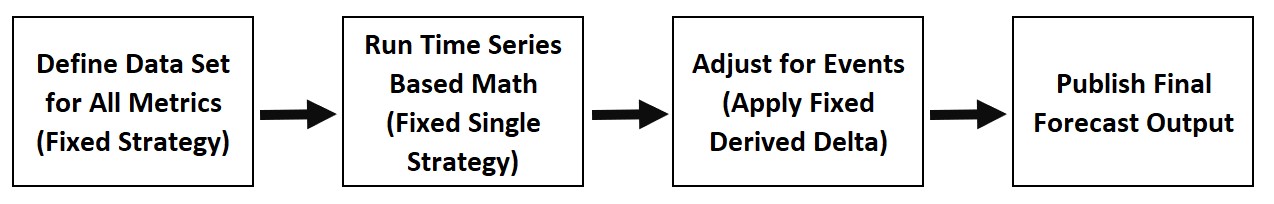

At a basic level, here’s the old process:

wp:image {“align”:”center”,”id”:14023} –>

While older systems allowed you to change the math, it was one-size-fits-all for the strategy in use for a given week. Same data selection, same math applied to all metrics (sales, items, customers, cases, etc.) The math used for forecasting involves linear programming, also known as time-series algorithms, with averaging or trending, or both. For each event, the system looks back into history and tries to determine how these events change the forecast. If an event has a historic impact of lifting sales 4 percent, then your base forecast sales are increased by 4 percent.

When fine-tuned as best you could for an “average week,” this left you with far less accurate forecasts whenever holidays, events, seasonality, weather and promotions were significant. Even recurring events such as pay periods, EBT releases, etc. created misses due to the day-of-week repositioning of these events. It was a hard sell to get managers to “trust the system” when the system could be fairly accurate 60 percent of the time, but wildly inaccurate whenever these variables arose. Meanwhile, the volatility of promotional events, competitive activity and weather has never been more pervasive.

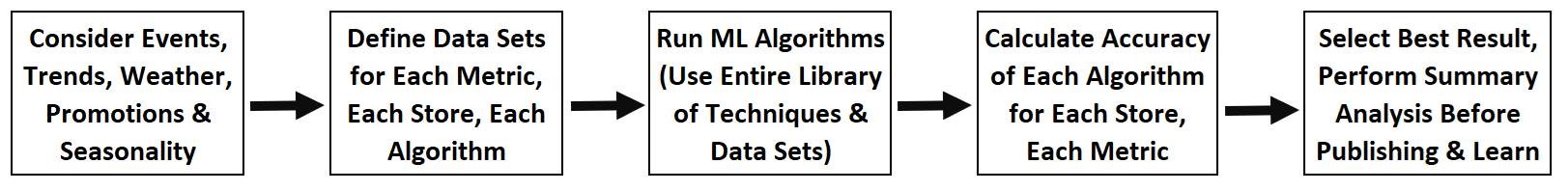

With a library of AI and ML algorithms, the process is more detailed and powerful. At an overview level, here’s the new process:

wp:image {“align”:”center”,”id”:14025} –>

Without getting too detailed, the differences stand out. Whereas the old methodology, which is still typical of most WFM forecasting solutions, relies on a single data set (last 4 weeks, last 8 weeks, etc.), the data set for the AI and ML algorithms varies by algorithm and is both informed by the events and selected appropriately for each algorithm. The data sets are also unique by store and for each metric. Events are handled after the fact in the first process, while they are fully integrated into the data set selection and adjustment process in the new approach. This layered-in approach produces better results in handling events, including transposition from day to day for those events that move from historical occurrences.

Once you do the math and apply the event adjustments, the old process is done. In the new processes, the result of each and every algorithm undergoes statistical analysis so that the most statistically reliable algorithm for that metric, for that store, for that type of week is selected. Even then, final macro analysis is applied to finalize the results. The difference is significant: it is akin to picking just one tool from your toolbox versus using and benefiting from the entire workshop of tools.

Don’t forget that learning algorithms learn. That means your tools are constantly recalibrating, resharpening and reengineering themselves based on your ongoing experience. AI empowers smart systems to get smarter, and ML enables algorithms to learn. If your current system isn’t getting smarter by learning from your history, how do the outputs get better for your stores? Accordingly, early adopters will create a leading competitive advantage.

Improved accuracy is indisputable

Find a vendor who will perform the analysis for you, and your results will be compelling. The newer approach to forecasting consistently wins. Vendors with old functionality will have you focus on higher-level forecasting like weekly sales. They find safety in big numbers that can cancel out daily variances. But the new approach always delivers better results. What’s even more telling is looking closer at daily store sales, daily department-level sales, and interval sales throughout the day. The results become ever more compelling as you look closer and closer at the scheduling impacts.

Translating higher accuracy into hours saved downstream

What’s the value of getting just $1,000 more accurate in forecasting per week? Simple store sales per hour (SPH) might initially lead you to calculate that value as 5 to 7 hours, depending on your current production rates. But consider that labor really gets planned at the daily level. So $3,000 over on one day, and $2,000 under on another start looking more like 25 to 35 hours misappropriated than 5 to 7. And, consider then that labor is most typically scheduled at the department level. The error from department to department can apply an even bigger multiplier to poorly positioned or ill-spent hours.

How many hours might be saved or better put to proper use varies with your current forecast inaccuracy. It’s up to you to determine the value of an hour saved and the value of an hour not spent where it is needed. Even with modest improvements, the numbers roll up into a lot of hours. Some of those hours are saved, some of those hours are better spent. Some of those hours are currently causing overtime. All hours come loaded with some level of benefit expense. Be reasonable in estimating, but brace yourself if you estimate the annual number across your enterprise. The numbers can be eye-opening, and the opportunity is compelling.

It’s an often-quoted statement that “you can’t get a good schedule out of a bad forecast.” It is also very true. Hours overscheduled in one department don’t justify service poorly delivered in another. Spending too many hours in the morning and too few hours in the evening creates inconsistent service expectations, jeopardizes sales and puts customer loyalty at risk. Of course, managers can adjust during the day or week in progress, but how easily does that happen with your current WFM tools, and at what cost? Accurate forecasting reduces variability for the week in progress and allows store personnel to execute your brand, your merchandising plans, and your service standards with far less waste.

The upstream value propositions for labor standards and labor modeling

If the downstream value is clear, how does forecasting improve the upstream process for labor standards and labor modeling? Many companies working to build a WFM platform for competitive advantage have work to do in systems, standards, data, standardized practices, and store-level execution. It is difficult, if not impossible, to address all of these elements at the same time. Long term, there’s a need for a paradigm shift to store execution supported by smart system best practices, rather than each manager doing their thing in their own way with unreliable system guidance.

Organizations that have focused on forecasting first can leverage basic approaches to calculating hours and be more deliberate about defining best practices, building engineered standards, and enhancing labor modeling. They’ll open the door to enable modeling of standards and drivers to engineered task time while they reduce wasted hours due to forecast inaccuracy.

For store managers, having a system you can rely on starts with an accurate forecast. It’s fundamental to the paradigm shift, and it’s a solid foundation for both upstream and downstream benefits to build upon. If you want competitive advantage through your WFM solution set, start by upgrading your forecast and build from there.