Luis Rojas-Romero, Industrial Engineer

Luz Hernandez, Industrial Engineering Analyst

When thinking about stocking a shelf, the immediate thought that comes to mind is the simple process of grasping an item and placing it on its designated shelf space. You might think it doesn’t require anything out of this world to do it, but the interesting part of stocking is what happens before an associate even reaches the aisle. Stocking is really a series of events that fills that empty space and achieves customer satisfaction. As retailers, caring about the state of the shelves means caring more–>about your customers’ needs and overall experience in the store. Using the right methods ensures stocking needs are satisfied. Having a defined, standardized process benefits your associates as well. Labor is time and time is money.

A “best method” is the series of steps and movements you can train your associates to practice to achieve efficiency and productivity. Implementing the best stocking or sorting method leads to great looking shelves, less backstock and better customer satisfaction.

What is the actual best method for your store?

Below are some key points to consider.

Steps. It is important to consider the distance associates are traveling. This impacts not only time but wear and tear on the associate. Some ways of reducing steps include:

- Store stocking carts close to the backroom.

- Sort like-product to the same stocking cart.

- If possible, have the night crew stage carts at the start of aisles for stocking first thing in the morning, eliminating multiple trips to the backroom.

Touches. Touching the product multiple times impacts time and efficiency, and it means more opportunities for the associates to use different methods. Multiple touches can be caused by misplaced product on the shelves or lack of rotation. Conditioning throughout the day can save significant time by having the shelves ready to be filled by more product.

Ergonomics. Like a good workout needs form and precision, so does a great stocking method. Performing the right body movements will increase speed and productivity. Standardized steps are key so that associates adapt quickly to using the right method, preventing injuries and reducing weariness. This has long-term impacts for the business in reducing injury claims and improving associate morale and retention.

Customer disruption. Some retailers prefer to perform stocking operations when the store is closed; however this is not always possible. Shelves often need to be conditioned or replenished throughout the day. Additionally, in certain situations it may be advantageous to have associates active on the sales floor to help promote customer service. If associates will be performing sales floor operations during shopping hours, it should be done with minimal disruption to customers. This means keeping access to displays open, reducing obstacles in the customers’ walking path, and reducing the appearance of trash on the sales floor.

With these considerations in mind, let’s look at a couple common methods used by retailers.

Stocking from pallet and case spotting

Stocking cases directly from the pallet is a very common practice. While this may seem like the most efficient method, it adds a significant amount of time to the task. Pallets received from the warehouse often include items from many different aisles, or sections of aisles; especially when store layouts vary.

When working directly from the pallet, associates are forced to bring the pallets to the sales floor to stock. There are some obvious drawbacks to this approach. When performed during opening hours, it creates obstacles and rubbish on the sales floor for customers to avoid. It also increases travel for associates.

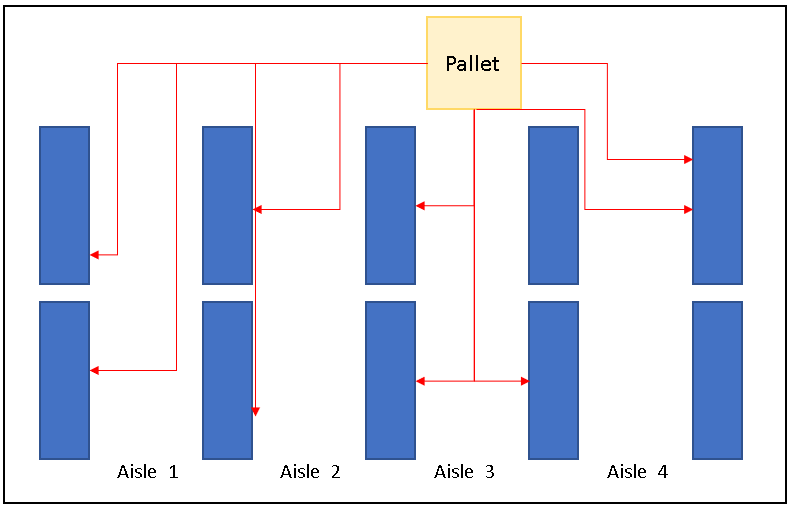

Let’s look at a typical grocery store setup. The associate places the pallet either in the middle of the sales floor or close to aisles that may contain many items in the pallet. They travel back and forward to complete stocking the aisles, making the process inefficient and unpleasant for the associate. In fact, this type of setup requires an associate to walk approximately 1 mile to complete the pallet.

If the associate is case spotting—that is, staging cases in the aisles to be stocked later—this method could drive up to 300 bends for associates per pallet. The result of all the extra walking and bending is more associate fatigue and higher likelihood of injury, not to mention the wasted time.

U-sort with mobile backstock

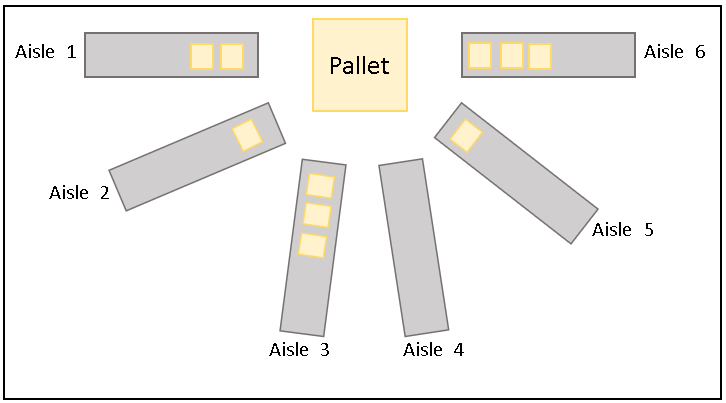

To reduce travel, many retailers have shifted to breaking down pallets before stocking. While this method requires the use of mobile carts, it significantly reduces time and motions when stocking. In this scenario, a U-sort technique is used, where the pallet is placed in the middle of multiple carts that have a designated aisle. One or two experienced associates, who have good knowledge of the sales floor, sort cases so they mirror the flow of the aisle on the cart.

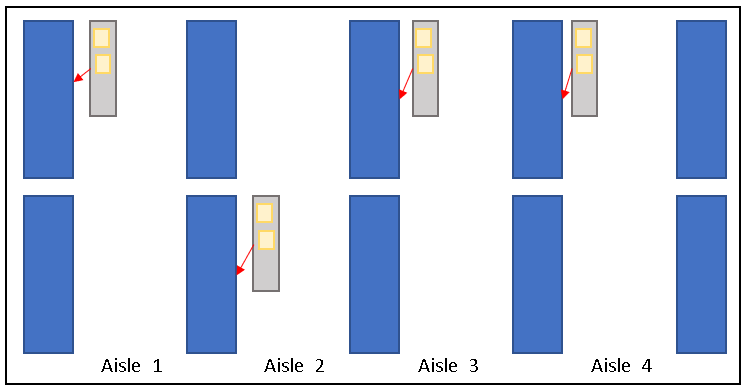

This enables the stocking associate to push items directly to the location they will be stocked, reducing back and forth travel. The amount of bending required is cut in half compared to the case spotting method. In fact, certain stocking carts can be equipped with a second, waist-high shelf to further reduce bending. Touches are also reduced in a variety of ways. Items that cannot fit onto the shelf simply remain on the cart to be worked later. Many carts are also equipped with an end attachment to store loose cardboard, reducing steps and touches to dispose of trash. Combine this with a work belt for associates that holds their cutter, shelf tags, gloves and other tools, and now you’ve creating a fully mobile workstation.

Determining the best method can require analysis, training and determination, but the fruits of implementing it are beneficial for a company that wants to be competitive and efficient in the market. As retailers, we know we succeed when we ensure customers and associates have the best possible in-store experience. This includes ensuring we keep the shelves stocked on time, efficiently and safely.

In our next blog post, we will explore key points to roll out a best method and gain adoption from the associates who will make it happen.