3 minute read

Food Safety Quadrant 1: Food Production

Nathaniel Sheetz, Senior Director of Product Management (United States)

Denise Cole, Senior Manager of Product Management – Food Safety (United States)

Neeta Dash, Senior Product Specialist (United States)

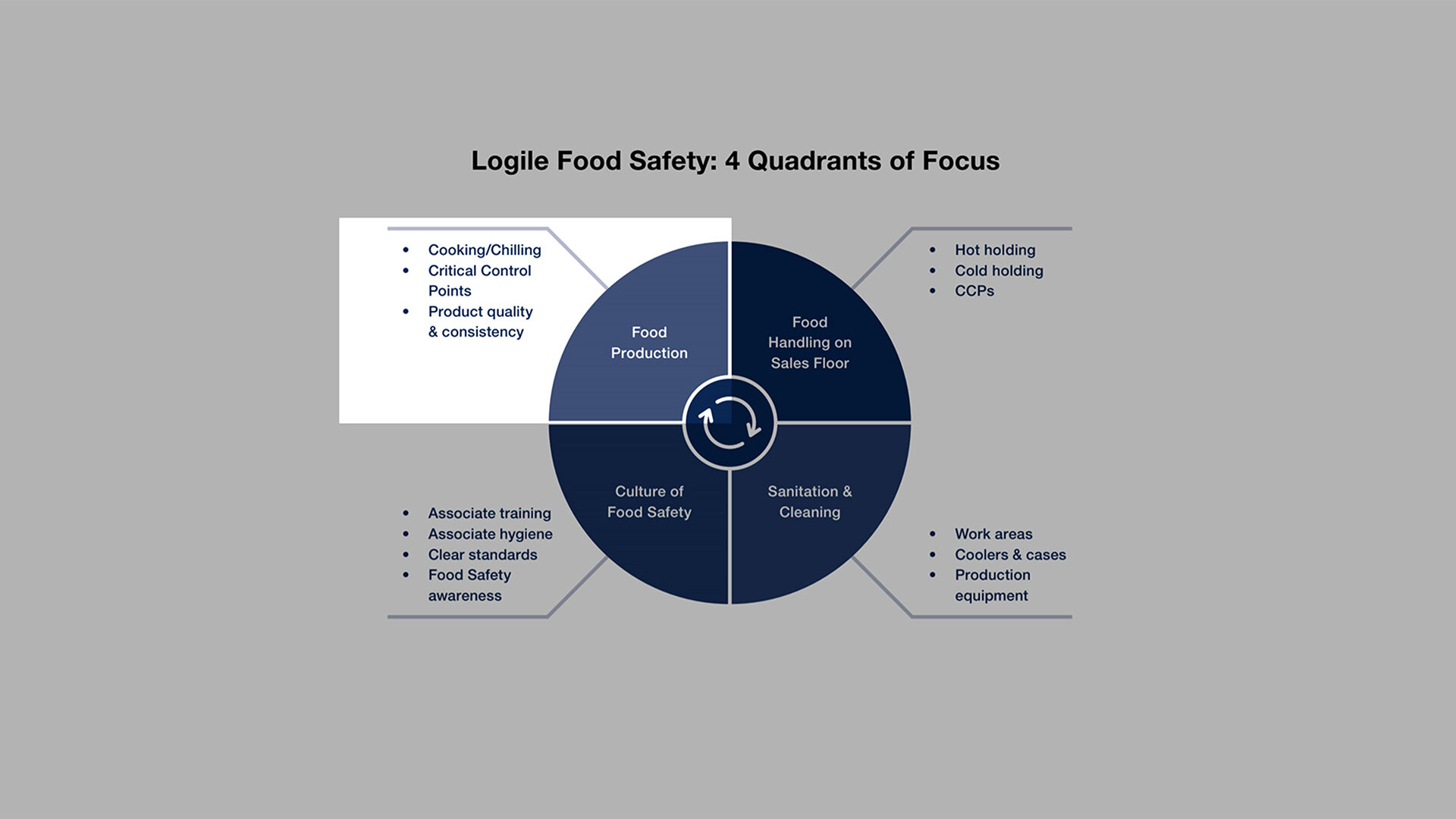

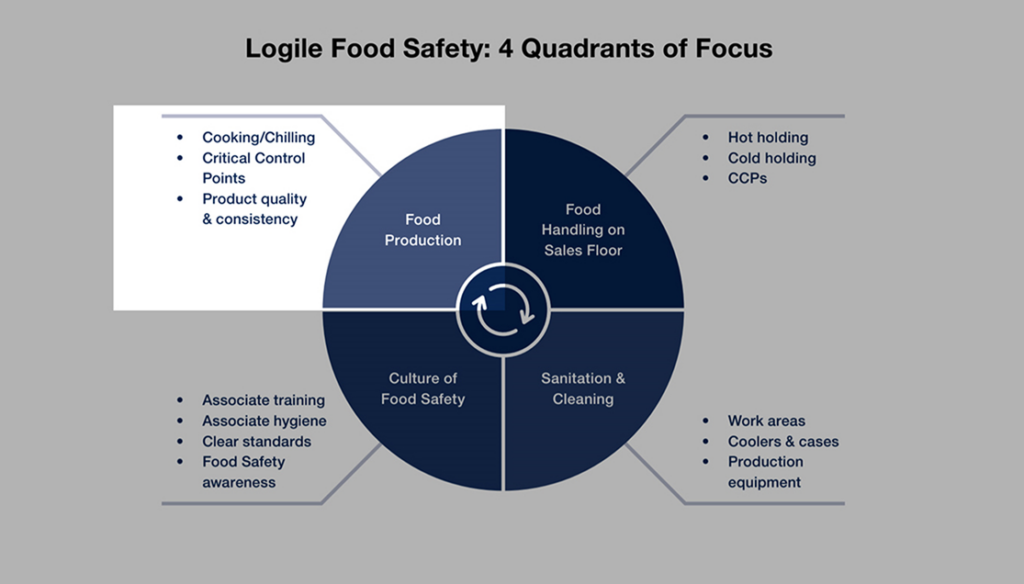

Our previous blog entry “Home Run: Elements of a Successful Food Safety Program” introduced the four quadrants of food safety (see diagram below), which are used in every successful food safety program. The first quadrant, dealing with food safety in food production, is not just for restaurants. Increasingly, grocery retailers take advantage of opportunities to sell freshly prepared food to their customers. As they do so, however, they must recognize and mitigate the new food safety risks.

Without such efforts, of course, the results can be catastrophic. One of the most infamous food safety failures in the United States, the 1993 E. Coli outbreak at Jack in the Box that killed four children and sickened over 700 people, could have been prevented by following food safety protocols. That outbreak and others like it have prompted food retailers to protect their customers and their businesses by adopting a systematic approach to food safety in food production environments.

Food safety in food production: The first quadrant is concerned with quality and consistency of prepared foods. Key areas of focus involve the development of recipes and process steps, compliance with established recipes/cooking processes, ingredient specifications, the development of critical control points for cook and chill times and temperatures, logs to record safe cook and chill temperatures, the proper maintenance of food coolers, and so forth.

The process of food production begins with the ingredients and the recipe that are used to make the finished product, and that’s where food safety begins as well. Ingredient specifications and sourcing are increasingly important to customers from a health and allergen perspective, and proper tracking of ingredient details helps companies in many ways. Not only can it help identify the root cause of any subsequent foodborne illness, but it also ensures accurate food labeling and consistency in product quality, thus cultivating customer loyalty.

Food safety practices through the batch production process are crucial, both in the handling phase and in the cooking phase. Proper food handling techniques must be followed, and employees should be proactively trained accordingly. The cook phase is obviously of major food safety concern for many products because heat is one of the main tools for killing pathogens in prepared foods. But even beyond the importance of ensuring safe temperatures, proper cooking procedures limit energy expenditure and ensure the highest possible food quality.

In many cases, prepared foods must pass through a chilling phase, either immediately after cooking or after some period of being held at a high temperature (such as unsold rotisserie chicken becoming an ingredient in chicken salad.) Food safety systems must track products through this process as well to ensure that food is not in the “danger zone” for too long. Employees must have clear guidance regarding the critical control points during the chill-down process, and their work should be facilitated by a system that helps them keep track of the various production batches that are at different points in their cooling process at any given time.

Beyond the food production process proper, a variety of ancillary activities are vital to maintaining food safety. For example, proper food handling practices must be observed, temperatures must be monitored, and appropriate cleaning and sanitization of equipment and work surfaces must be done when necessary. All this requires that employees know exactly what to do, how to do it, and when to do it. In other words, the numerous preventative steps that must be taken to keep food safe must become a fully integrated part of the recipe for the entire food production process.

These high-level considerations represent just the tip of the iceberg of risks and challenges associated with safe food production. A comprehensive food safety program must be designed to present, manage and monitor all behind-the-scenes activities that take place from the moment ingredients are received to the moment the final product is rung up. And because deviations will certainly occur, food safety systems must be able to capture deviations, instruct employees to take specific corrective actions, and confirm that such actions have been completed.

Future posts in this series on the four quadrants of a successful food safety program will explore how food handling on the sales floor, sanitation and cleaning, and a culture of food safety also play a role in ensuring food safety in food retail environments.