5 minute read

Safety First: Establishing the Right Food Safety Workflows

Nathaniel Sheetz, Director of Product Management

Neeta Dash, Product Management Analyst

In the previous installments in this series on implementing effective food safety technology solutions (see part 1 and part 2), we explored the analysis and planning necessary to meaningfully improve compliance and reduce risk through the course of a food safety implementation project. By evaluating the current state of food safety in the organization, as well as any perceived shortcomings, stakeholders develop a starting point for evaluation of elements of a food safety program implementation.

Such elements may be “food safety proper”—for example, cooking, chilling, holding and sanitation. But related processes, such as product time controls, meat grind logs, and even larger efforts like production planning and shrink management could be considered as well. The scope will depend on the organization’s tolerance for short-term change and the capabilities of the solution being implemented.

In the interest of effectively managing change and delivering quick wins in high-priority areas, most companies choose to focus on high-risk, high-visibility food safety processes during the initial wave of a food safety implementation. The top tier typically includes:

- Cook temperature logs for items sold hot

- Cook and chill temperature logs for items sold cold

- Holding temperature logs of both cold and hot items

Based on organizational priorities, some second-tier elements are also often included, such as:

- Sushi rice pH logs

- Sanitation activity logs

- Product time control

- Meat grind logs

This post will focus on the three processes identified above as “top tier” priorities. Examining these processes in depth will reveal how software can support robust handling of corrective actions, notifications, reviews and more.

Cook temperature logs

In many ways, capturing cook temperatures is one of the simpler food safety processes. As each item comes out of the oven, its core temperature is captured. If it is acceptable, the product is typically placed in a hot case for sale. If it is too low, the item is returned to the oven for additional cooking. (The chilling process is handled separately, below.)

Despite the apparent simplicity, however, cook logs involve several variables. Most important is the required temperature of the specific item being cooked, which impacts food quality as well as safety. Fish products, if cooked to the same temperature as rotisserie chicken, will be overdone and unappetizing to customers. Another key variable is the number of temperature captures required for each batch. Does a batch of 36 rotisserie chickens require a single compliant temperature reading or several?

Retailers must weigh their priorities and the capabilities of their solution. Item-specific minimum and maximum temperature thresholds—configured to comply with local food codes and tied to items via a pick list or a barcode scan—can ensure that foods sold have been cooked to a safe temperature without being overcooked. Furthermore, standards should be established and built into the solution to indicate how many temperatures should be captured for large batches.

Cook and chill logs

Cook and chill logs share the same initial step as cook logs, that is, each item must be cooked to a safe temperature and this temperature must be logged. Afterward, however, the chilling process adds complexity.

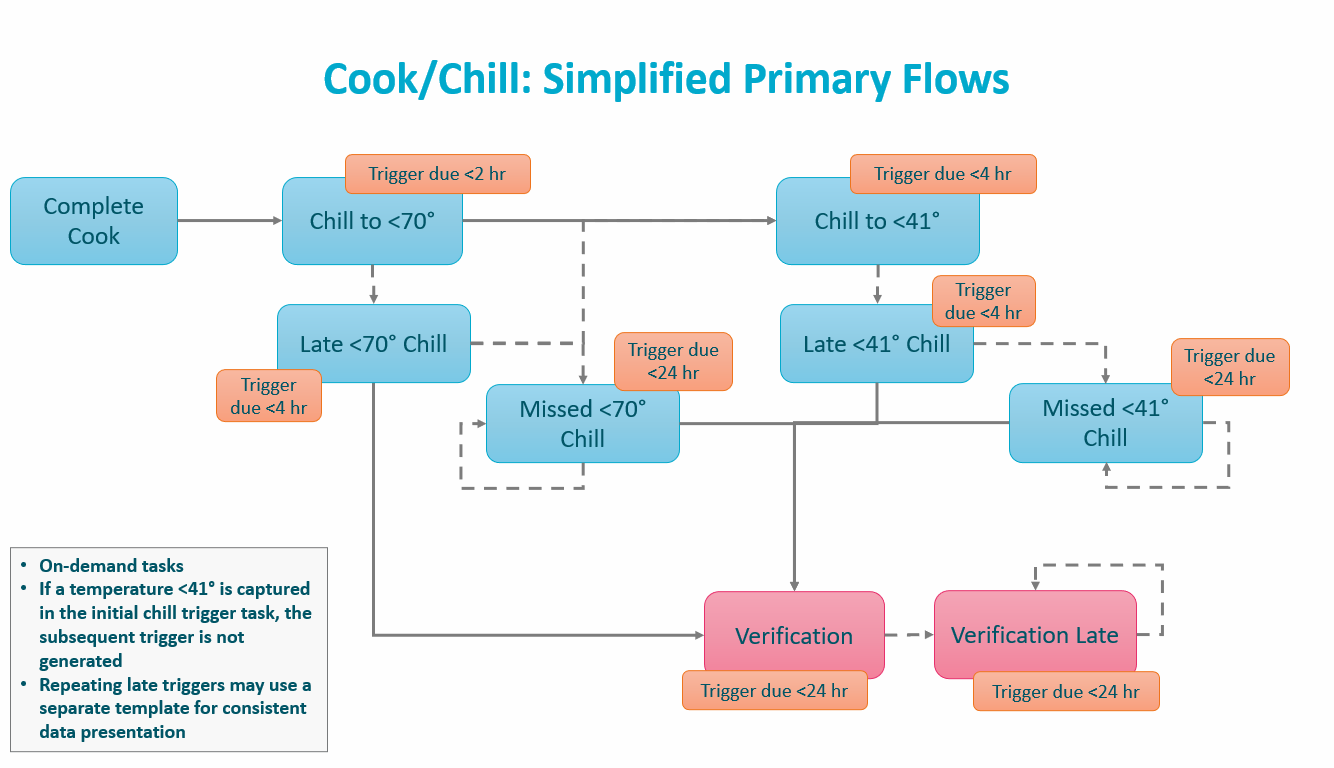

Unlike cook temperatures, the chill-down process is typically the same for nearly all foods. The FDA food code, for example, states products ought to be chilled to below 70° F within two hours, and to below 41° F within a total of six hours. Still, some complexities must be worked out. Most obviously, in this scenario, the solution must require a second temperature capture only if the first one is above 41° F. If a blast chiller is used, for example, and the product drops below this threshold within two hours, then no additional temperature capture should be required.

A second complexity is determining how non-compliant temperatures should be handled. A 90° temperature captured as part of a two-hour cool down task may indicate that the product must be discarded because it hasn’t chilled quickly. But if the temperature was taken early—say only one hour after the item came out of the oven—then simply putting the item back in the chiller for another hour is more appropriate.

Finally, a third challenge is determining what to do when temperature checks are not performed in time. Should such product be discarded? What kind of manager notifications and follow-up tasks should be put in place? Here, different paths might be taken based on each organization’s priorities, the local food code, and the actual conditions in the store.

In all three cases, as before, the organization must decide which workflows are worth building, and the solution must deliver the content of those workflows in such a way as to make it simple for the end user. Thus, an organization may insist on the ability to skip the six-hour check if the two-hour check produces a temperature below 41° F. It may choose to prompt users to continue chilling foods when additional time is available but adopt a simple “discard the product” policy for late cooling temperature checks.

Holding temperatures

Perhaps the greatest opportunity for process complexity is found in holding temperatures. Key parameters include:

- Identify the product checked, or only the case?

- Use a single temperature threshold for all items in the department, or make this item-specific? Some items, such as raw eggs and roasts, may have different temperature requirements in some situations and locales.

- Set a specific schedule that must be followed, or allow stores leeway to take temperatures more often than necessary if it helps them account for peak customer flows?

- Under which circumstances should products be rechilled, reheated and discarded?

- What should happen if tasks are not completed on time?

Here, as before, organizations can take dramatically different approaches while keeping food safe. One organization, in order to maximize simplicity, might set a fixed schedule for temperature checks, not log specific items, use a single temperature threshold for cold holding items, and always discard non-compliant items. This simplicity comes at a cost—less flexibility, greater shrink and less transparency.

With a powerful food safety solution, however, more complex processes can be implemented without burdening the user. Items could be identified via dropdown selection or barcode scan, and specific temperature thresholds that comply with local food codes could be configured for each one. Temperatures could be taken when convenient for each department, so long as maximum time limits are always respected. And appropriate workflows can guide employees to rechill or reheat products when safe to do so.

Conclusion

When implementing a food safety solution, it’s worth evaluating existing food safety processes and weighing the benefits of adjusting those processes to take advantage of solution features to improve operational efficiency and food product quality and consistency, as well as food safety compliance. Software solutions can then guide store users through the critical control points of these food safety processes, prompting them to take timely, appropriate actions that maximize compliance and reduce waste and risk.

In future entries in this series, we’ll continue our exploration of key implementation considerations, including hardware, system configuration and rollout strategy.