The Challenge

Food safety is non-negotiable. For grocery, convenience, and foodservice retailers, even a single misstep can trigger recalls, fines, and brand damage. Yet too many organizations still rely on paper logs, disconnected tools, or manual checks that are error-prone and difficult to scale.

The Logile Difference

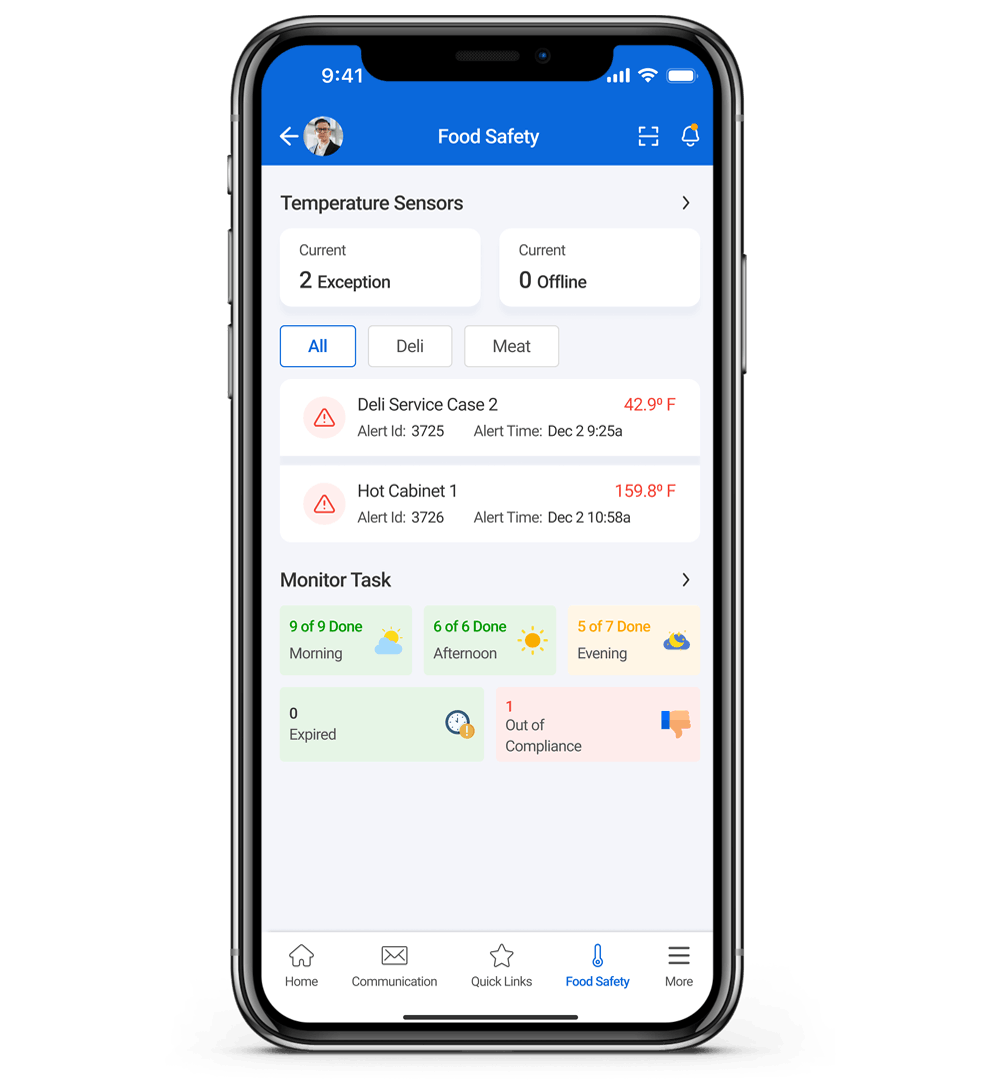

Logile Food Safety Solutions is an integrated, digital-first platform that puts food safety on autopilot. It combines three powerful components into a single system:

- Task-Based Execution: Digitize food safety checklists, cleaning, recalls, training, and audits with built-in compliance logic and SOPs.

- Thermal Intelligence Monitoring: Proprietary wireless sensors mimic real food behavior, providing 24/7 temperature monitoring for hot and cold holding conditions.

- Centralized Plan Management: Standardize, document, and control food safety strategies at scale with enterprise visibility and accountability.

Outcomes

Key Capabilities

Automated Task Execution

Assign and track temperature checks, sanitization, and recalls in one system.

Thermal Intelligence Sensors

Proprietary design with thermal inertia fluid for more accurate food-level data than air loggers.

Real-Time Alerts & Escalations

Detect risks instantly and trigger corrective actions.

SOP Integration

Associates follow guided workflows with recipes, safety steps, and photo verification.

Centralized Food Safety Plans

Enterprise-level oversight with store-level execution and accountability.

Data-Driven Insight

Optimize equipment, reduce shrink, and measure compliance performance across locations.

Who's It For?

How It Works

- Centralize and Standardize All Food Safety Protocols: Replace inconsistent paper-based systems with a single digital hub for all HACCP/FSMA workflows, checklists, and SOPs. Ensure every store executes procedures perfectly and consistently.

- Monitor Conditions with Unmatched Precision: Go beyond manual spot-checks. Our Thermal Intelligence sensors provide continuous, 24/7 monitoring of temperatures at the food level, not just the air, capturing the true safety of your products.

- Enable Instant Corrective Action with Guided Resolution: Automate your response to any violation. The system instantly alerts managers and creates specific corrective tasks with step-by-step coaching and requires photo proof of completion to verify issues are resolved.

- Simplify Audits and Reporting with a Digital Paper Trail: Transform audit day from a stressful scramble into a simple click. Generate comprehensive compliance reports from immutable digital logs, providing auditors with immediate, enterprise-wide visibility.

Integrations

Our food safety compliance is automated through integrations with task management for assigned checks, Thermal Intelligence™ for real-time monitoring, and BI/audit systems for seamless reporting and verification.

Explore Logile's tightly integrated yet modular solutions—each one powerful alone,even better together.

Forecasting

15-minute, promo- and weather-aware forecasts for sales, items, traffic, and staffing.

Labor Modeling

Streamline your store processes, manage inventory and develop accurate labor standards, labor models, forecasts and budgets.

Staff Planning

Build smarter staffing plans before you schedule

Budgeting

Dynamic, store-level labor & sales budgets that adjust weekly—not yearly

Scheduling

Task‑based, wall‑to‑wall schedules with effectiveness scoring and predictive‑scheduling compliance.

Time & Attendance

Accurately and efficiently automate the process of collecting, calculating and reporting of associate work data.

Task Management

Bring order to the frontline. Ensure every task gets done.

Fresh Item Management

Forecast → recipe → production → labeling on mobile to cut shrink and lift freshness.

Food Safety Solutions

Digitize checks, automate corrective actions, and centralize plans—audits made easy.

FAQs

Most tools are point solutions that only digitize logs or manage tasks. Logile unifies task execution, wireless temperature monitoring, and centralized plan management in one platform, giving operators both compliance and real-time control.

Our Thermal Intelligence sensors use thermal inertia fluid to mimic how real food heats and cools. Competitors use air temperature loggers, which can be inaccurate. With Logile, you get food-level accuracy and actionable insights.

Yes. Routine checks and logs are automated, saving 30–50% of labor time while eliminating errors and inconsistencies. Stores still have the option to record exceptions or photo verification when needed.

Every task and temperature reading is recorded digitally with timestamps, corrective actions, and escalation history. During inspections, managers can instantly pull compliance data instead of relying on paper binders.

No. Associates use a simple mobile interface with guided workflows, recipes, and SOPs. Alerts and next steps are clear, and managers gain oversight without extra complexity.

Retailers typically achieve payback within 12–18 months, driven by shrink reduction, labor efficiency, reduced consumables, and energy savings.

- Food Safety Leaders → Confidence in compliance and audit performance

- Store Ops Teams → Easier execution with fewer errors and less paperwork

- Asset and Facilities Managers → Better visibility into equipment performance and maintenance needs

- Executives → Brand protection and measurable financial impact