LogileThermal Intelligence™

Cut waste, save labor, and protect food quality with the most accurate temperature monitoring system in food retail.

The Challenge

Food safety and quality depend on accurate, consistent temperature control. Yet most retailers still rely on manual checks, clipboards, or hardwired thermometers that measure air at the compressor, not the actual product. The result is blind spots, wasted food, and unnecessary compliance risk.

The Logile Difference

Logile Thermal Intelligence™ (TI) is the next generation of temperature monitoring. Using patented wireless sensors with engineered thermal inertia fluid, TI mimics how real food heats and cools, giving you the truest picture of product-level temperature available today.

Outcomes

Key Features

Thermal Inertia Technology

Sensors replicate food behavior for unmatched accuracy

Hot, Cold, and Mobile Asset Monitoring

Cover every case, well, cart, and cooler without hardwiring

Real-Time Alerts

Early warnings with cause analysis and corrective prompts

24/7 Cloud Visibility

Enterprise and store dashboards accessible from any device

Operational Insight

Asset performance data for smarter maintenance and energy management

Automated Compliance

Replace paper logs with digital records that auditors trust

Who's It For?

How It Works

- Deploy Effortlessly with Wireless Sensor Technology: Begin monitoring in hours, not days. Our wireless sensors install quickly without costly hardwiring or disruptive construction, allowing for flexible placement and easy scaling across your entire enterprise.

- Customize Alerts for Your Specific Compliance Needs: Define precise temperature and humidity thresholds for each individual cooler, freezer, and display case. Ensure you're monitoring exactly what matters for your specific products and HACCP plans.

- Gain Uninterrupted Visibility from Anywhere: Access real-time thermal data and cloud-based dashboards from any device. Our system continues monitoring and storing data even during internet outages, ensuring you never lose visibility into your critical assets.

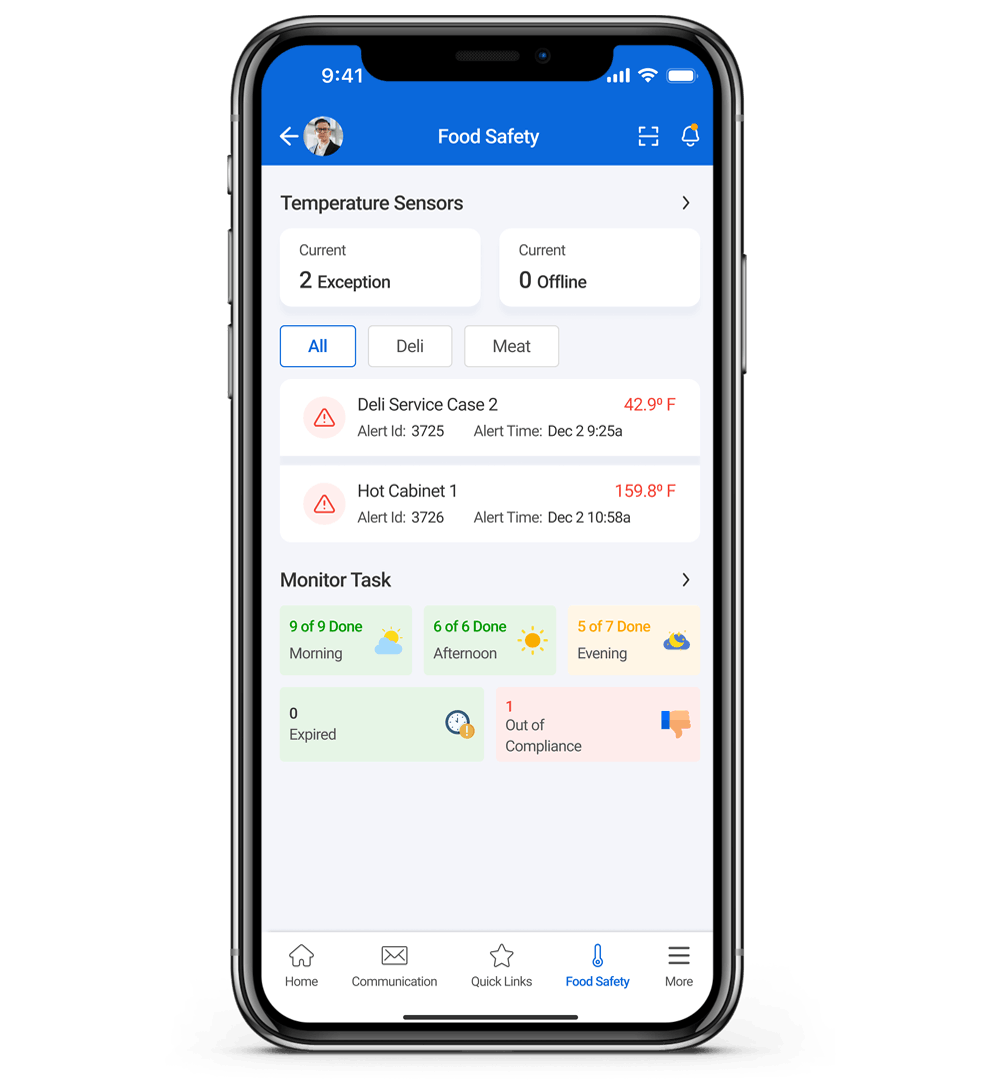

- Automate Incident Response to Prevent Loss: Move from reactive problem-solving to proactive protection. The system instantly alerts designated managers via mobile push notifications and automatically creates corrective tasks in Logile to resolve issues before they impact inventory.

- Optimize Performance and Reduce Energy Costs: Transform compliance data into operational intelligence. Analyze long-term performance trends to identify failing equipment early, validate maintenance efforts, and uncover opportunities to reduce energy consumption across your facility.

Integrations

Transform temperature data into automated workflows. Our sensors integrate with task management for alerts, food safety software for compliance, and facility/CMMS via API to dispatch maintenance instantly.

Explore Logile's tightly integrated yet modular solutions—each one powerful alone,even better together.

Forecasting

15-minute, promo- and weather-aware forecasts for sales, items, traffic, and staffing.

Labor Modeling

Streamline your store processes, manage inventory and develop accurate labor standards, labor models, forecasts and budgets.

Staff Planning

Build smarter staffing plans before you schedule

Budgeting

Dynamic, store-level labor & sales budgets that adjust weekly—not yearly

Scheduling

Task‑based, wall‑to‑wall schedules with effectiveness scoring and predictive‑scheduling compliance.

Time & Attendance

Accurately and efficiently automate the process of collecting, calculating and reporting of associate work data.

Task Management

Bring order to the frontline. Ensure every task gets done.

Fresh Item Management

Forecast → recipe → production → labeling on mobile to cut shrink and lift freshness.

Food Safety Solutions

Digitize checks, automate corrective actions, and centralize plans—audits made easy.

FAQs

Most systems measure air temperature at the compressor, which doesn’t reflect actual food conditions. TI uses patented sensors with thermal inertia fluid that mimics how real food heats and cools, delivering the most accurate product-level monitoring available.

Yes. TI automates routine checks with 24/7 wireless monitoring and digital recordkeeping. This saves 40–60% of labor time, eliminates paper logs, and ensures consistent compliance across all locations.

Yes. TI is the only system designed to monitor hot holding, cold storage, and mobile assets like prep carts or grab-and-go coolers, all in real time.

Most retailers recover their investment in under 12 months through waste reduction, labor savings, and energy optimization.

Wireless TI sensors are simple to install. They require no electrical or plumbing work and can be deployed quickly without disrupting store operations.

All readings are stored digitally with timestamps, corrective actions, and alerts. Auditors and inspectors can access detailed logs instantly, improving scores and reducing the risk of penalties.

- Food Safety Leaders → Confidence in compliance and readiness

- Store Managers → Less manual work and fewer errors

- Facilities Teams → Asset performance insights for smarter maintenance

- Executives → Lower risk, better margins, stronger brand reputation