LogileFresh Item Management

Cut waste by 20–40%, safeguard food safety, and lift margins with real-time, store-level control.

Why Fresh Matters

Fresh departments account for more than 30% of grocery and convenience store traffic and play a critical role in customer loyalty, but they are also the most difficult to manage. Static production methods lead to waste, lost sales, and inconsistent quality, while rising pressure to reduce shrink, meet food safety standards, and control labor costs makes operational excellence in fresh a business imperative.

The Logile Difference

Logile Fresh Item Management is a mobile-first, store-level platform that transforms how retailers run fresh operations. It goes beyond forecasting to deliver dynamic, demand-driven production planning that aligns labor, inventory, and food safety in one connected system. Shrink is reduced, freshness is maximized, and associates execute with confidence using guided mobile workflows and real-time data.

Results & Outcomes

Key Features

AI-Driven Forecasting

Self-learning models account for sales, shrink, promotions, seasonality, and even weather. This improves accuracy and ensures production reflects real demand.

Guided Production Plans

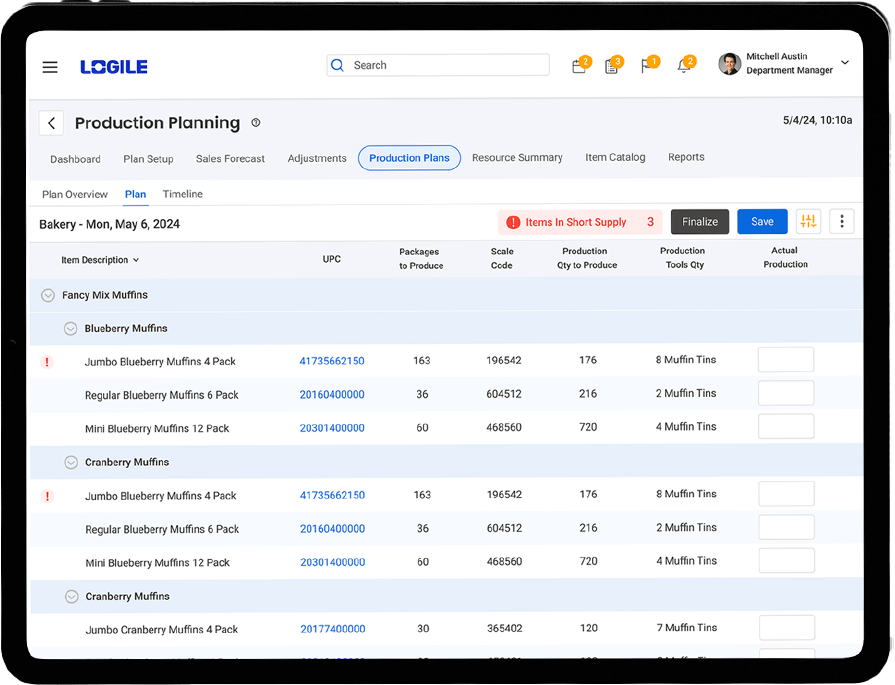

Tablets deliver clear production plan visibility, showing associates what to make, when, and how much. No guesswork or paper checklists.

Mobile Task Execution

Mobile tasks prompt associates to carry out activities such as shrink adjustments and inventory updates for clear, consistent execution.

Recipe Management & Digital Cookbook

Centralized recipes push automatically to stores, scales, and mobile devices, with real-time updates reflected in Cookbook. Visual instructions, allergens, nutrition, and batch sizes help ensure consistent quality and compliance.

Yield Management

Track yields from cutting tests and production, then connect insights directly to ordering and costing to drive better decisions and improved accuracy and efficiency.

Scale Management

Maintain accurate file integrity, nutrition facts, ingredients, and weight and measures compliance with complete corporate control. Every item labeled correctly—automatically synced across stores.

Recipe-to-Replenishment Integration

One unified flow ties forecasting, production, labeling, and inventory together. When upstream changes occur, the entire system adapts instantly.

Production Planning

Automatically generate optimized batch sizes and production schedules directly from AI forecasts. Ensure you make the right quantity of each item to meet demand precisely.

Grind Log

Digitally track raw material usage by batch for full compliance and accurate costing. Maintain perfect lot traceability from receiving to final product.

Who's It For?

How It Works

- Generate Precision Forecasts for Every Item: Move beyond daily guesses. Our AI-driven models forecast production needs at the individual item and recipe level, accounting for sales history, promotions, seasonality, and even weather to ensure you produce exactly what you'll sell.

- Execute Flawlessly with Guided Production: Empower your kitchen teams with a mobile "digital cookbook" that provides clear batch sizes and step-by-step instructions. Eliminate guesswork and ensure consistent quality and portion control across all locations and shifts.

- Ensure Automatic Compliance and Accurate Labeling: Eliminate labeling errors and compliance risks. The system automatically generates accurate nutrition facts, ingredient statements, and allergen labels from your centralized recipes, ensuring every package meets regulatory requirements.

- Create a Self-Learning Production System: Close the loop between planning and performance. Track yields and compare them against forecasts, feeding this data back into our AI models to continuously improve forecast accuracy and reduce waste over time.

Integrations

Our Fresh Item Management seamlessly integrates with WFM/scheduling for optimized labor.

Explore Logile's tightly integrated yet modular solutions—each one powerful alone,even better together.

Forecasting

15-minute, promo- and weather-aware forecasts for sales, items, traffic, and staffing.

Labor Modeling

Streamline your store processes, manage inventory and develop accurate labor standards, labor models, forecasts and budgets.

Staff Planning

Build smarter staffing plans before you schedule

Budgeting

Dynamic, store-level labor & sales budgets that adjust weekly—not yearly

Scheduling

Task‑based, wall‑to‑wall schedules with effectiveness scoring and predictive‑scheduling compliance.

Time & Attendance

Accurately and efficiently automate the process of collecting, calculating and reporting of associate work data.

Task Management

Bring order to the frontline. Ensure every task gets done.

Fresh Item Management

Forecast → recipe → production → labeling on mobile to cut shrink and lift freshness.

Food Safety Solutions

Digitize checks, automate corrective actions, and centralize plans—audits made easy.

FAQs

Most systems stop at forecasting or inventory tracking. Logile connects the entire process from forecasting to recipe execution, labeling, yield management, and compliance, all in one integrated platform.

Through Scale Management

Retailers typically achieve 20–40% shrink reduction within the first 14–18 months, along with faster inventory turns and improved forecast accuracy.

Yes. Food safety protocols are built into recipes, task workflows, and labeling. Associates follow guided steps on mobile devices, and managers gain visibility into compliance with full audit trails.

Associates receive mobile tasks via Cookbook with recipes, batch sizes, allergens, and safety steps. This reduces training time, removes guesswork, and ensures consistent execution across every store.

Yes. Recipe and label updates flow automatically from corporate to store scales, ensuring every item has accurate pricing, nutrition, and allergen data.

Most retailers see payback within 14–18 months, driven by shrink reduction, labor efficiency, and better capital utilization.

Department managers in deli, bakery, and produce, along with associates preparing fresh food, use it daily. Corporate teams in operations, merchandising, and food safety also benefit from real-time visibility and control.